|

| August 04, 2015 | Volume 11 Issue 29 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Wheels:

Ford using Carbon3D's "Terminator 2" CLIP 3D-printing technology

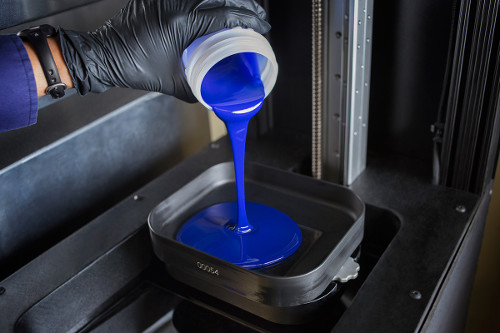

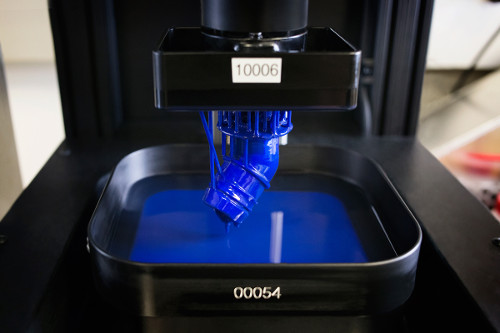

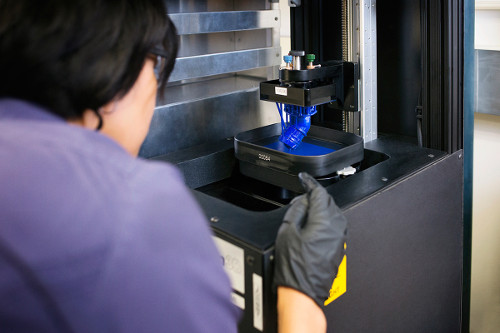

Ford's early access to the pre-release CLIP-based device from Carbon3D is accelerating innovation in materials and product design. [All images courtesy: Carbon3D, Inc.].

Engineers at Ford Motor Company have been beta testing Carbon3D's Continuous Liquid Interface Production (CLIP) technology, the mind-blowing (and we don't use that phrase often) 3D-printing method that grows plastic parts from a pool of heated resin. (See Designfax April 14.)

In December 2014, Ford began testing a pre-release version of Carbon3D's first CLIP-based device, which was inspired, in part, by a scene in "Terminator 2."

The results so far?

"We're thrilled," says Ellen Lee, Team Leader, Additive Manufacturing Research at Ford. "The parts we've produced are mechanically strong, just like injection molded parts. That's the target we've set for an automotive-grade part."

Ford has been using conventional 3D-printing technologies to prototype new product designs for more than 20 years. Recently, the company developed a dedicated new additive manufacturing research program to explore the potential of new technologies to manufacture vehicle-ready parts. Carbon3D's CLIP technology is allowing Ford to move more quickly from ideas to production. The automaker has already successfully applied the technology to current and future vehicle model designs, and is leveraging CLIP to research new automotive relevant materials.

Carbon3D's CLIP technology uses a tunable photochemical process instead of the traditional mechanical approach, eliminating some of the shortcomings of conventional layer-by-layer 3D-printing technology, to rapidly transform 3D models into physical objects. CLIP carefully balances the interaction of UV light (which triggers photo polymerization) and oxygen (which inhibits the reaction), allowing for continuously grown objects from a pool of resin. The resulting parts boast mechanical properties that are applicable for a range of industries, including aerospace, industrial goods, medical, dental, and, of course, automotive. These predictable mechanical properties allow for part creation across the range of needs for Ford vehicles including under-the-hood, interior, and high strength-to-weight-ratio parts.

Prototype parts like this oil connector are "grown" at Ford using Carbon3D's CLIP-based device.

Ford says it has been able to unlock mechanical properties unattainable with any other 3D printing technology.

The array of materials and mechanical properties needed for automotive applications has often relegated conventional 3D printing to conceptual prototyping. With only a handful of available materials, and final printed parts that are sometimes shale-like and weak, the resulting mechanical properties of conventionally 3D-printed parts are often unsuitable for in-vehicle use. Conventional technology can also take overnight print runs or even days to execute, which has left designers and engineers waiting for prototypes to materialize.

In one application, Ford worked to produce elastomer grommets for the Focus Electric and tested them against those made by traditional 3D-printing methods. Not only were the grommets made in less than a third of the time with the CLIP-based device, the material properties were much closer to the final desired properties for the part. The grommets are used in a space in the door of the vehicle between the door and the body side. The grommet allows wiring to be protected from being cut and damaged by sheet metal inside the vehicle.

In a similar study, several alternative designs were evaluated for a damping bumper part on the Ford Transit Connect using CLIP technology. The game-changing manufacturing time allowed engineers to make design iterations much more quickly than with traditional methods.

Most recently, Ford needed to address a major engineering issue that arose after placing a V8 engine into a new vehicle body design. The vehicle's design created an unreachable oil filler cap, because the engine sat lower and further back under the hood. The product engineering team realized the opportunity to quickly address the issue using Carbon3D's CLIP-based device. The team was able to rapidly design, prototype, and manufacture an oil connector using rigid polyurethane and elastomer materials to access the oil fill tube without needing major redesigns to several components of the vehicle.

Beyond the current vehicle applications, Ford has also been able to expand its own materials research because of CLIP's gentle process and high-quality polymeric materials. To date, the team has tested several materials, including resins reinforced with nano-size particles. The automaker is eager to further investigate resin modifications for improved mechanical properties and to consider the creation of thermally and electrically conductive materials for future vehicle applications.

"The chemistry that Carbon3D has based their resins on has significant potential to yield functional, durable materials. We're excited to be able to tap into their technology to create new automotive relevant materials and applications for digital manufacturing. It's revolutionary," says Lee.

Sources: Carbon3D, Ford Motor Co.

Published August 2015

Rate this article

View our terms of use and privacy policy